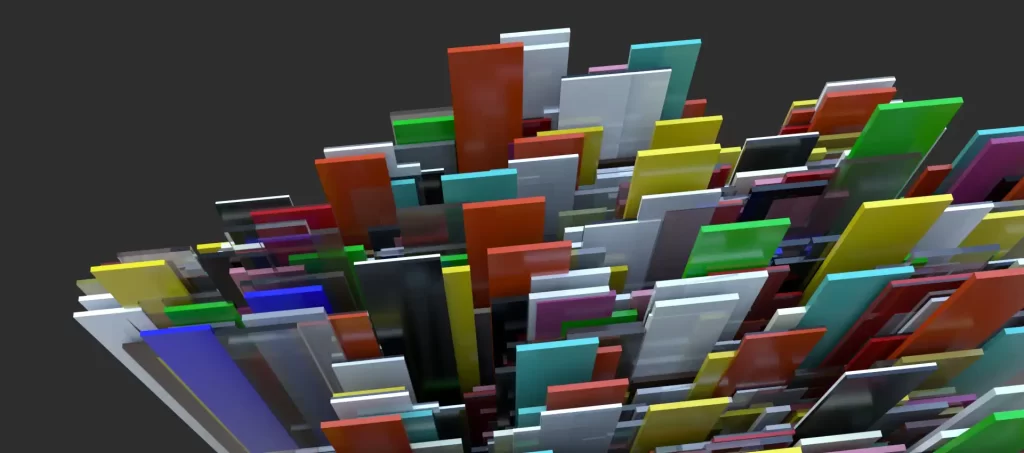

Color Sheet

Color Sheet Description

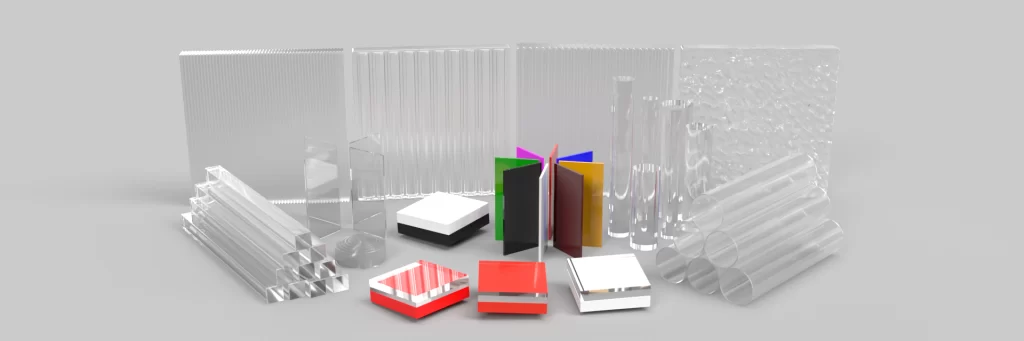

Extrusion color plate (acrylic plate) is a rich color of acrylic products, its manufacturing process is similar to extrusion plate, but in the addition of raw materials and process steps are different.

First, compared with the ordinary extrusion plate, the extrusion color plate raw material added pigment or pigment particles. These pigments can be organic or inorganic and are used to give the board a specific color and effect.

The pigment is added to the acrylic resin at the feed port of the extruder. Pigments and resins are mixed and melted to form a melt.

The melt is then pushed by the extruder's screw and extruded into continuous color plates through the extrusion outlet of the mold. The mold shape and structure determine the thickness, width and texture of the final product.

During the extrusion process, the molten material is rapidly cooled by the cooling coiling device, so that it changes from molten state to solid state. The cooling method can be air-cooled or water-cooled to control the temperature and hardness of the plate.

After cooling is completed, the color plate is stretched or cut through a traction roller or cutting device to get the desired size and length.

Finally, after quality inspection and testing, extrusion color plate was confirmed as qualified products. Quality inspection includes color consistency, dimension measurement, appearance inspection, etc.

The extrusion process of color plate has the advantages of high efficiency, stability and controllability. By adding different colors of paint, a rich variety of color plates can be created for a variety of indoor and outdoor decorative needs.

Our company adopts advanced extrusion color plate process, to ensure that the product color is bright, uniform, and has excellent physical properties. We continue to optimize the process flow and quality control, in order to provide high quality extrusion color plate products to meet the personalized needs of customers.

Plan and what you might want to know

- If you want to know the scope of the product.

- About our arrangements and expectations for the production plan.

- What can we do for you?