Cast Sheet

Production process of cast sheet.

Cast sheet is a high-quality material manufactured using advanced casting techniques. It offers outstanding transparency and optical performance, making it ideal for applications that require high clarity and visual quality. Additionally, it has excellent physical properties and mechanical strength, with high impact resistance and bending strength. Cast sheet is easy to process, allowing for various shaping and design requirements. It also exhibits good weather resistance and chemical stability, maintaining its performance even under UV exposure and resisting corrosion from acids and alkalis. In summary, cast sheet is a premium material known for its transparency, durability, versatility, and resistance to environmental factors and chemicals.

Plan and what you might want to know

- If you want to know the scope of the produc.

- About our arrangements and expectations for the production plan.

- What can we do for you?

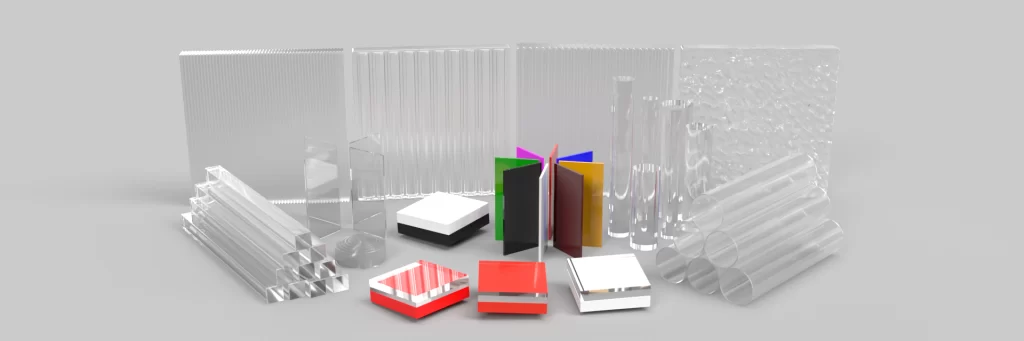

Casting plate (acrylic plate) is an acrylic product made by pouring a liquid acrylic mixture and curing in a mold. The following is the process of casting the slab:

Prepare the mold: Select the appropriate mold and make the mold according to the desired size and shape. The mold can be silicone mold, wood mold or metal mold, etc.

Prepare the acrylic mixture: Mix the acrylic resin and hardener in a specific ratio. Pigments, fillers, or other additives can be added as needed to achieve specific effects and properties.

Pouring process: Pour the prepared acrylic mixture into the mold slowly and evenly, ensuring that the liquid fills the mold and that there are no air bubbles or impurities.

Curing process: Under appropriate temperature and humidity conditions, the acrylic mixture will gradually cure and harden. This usually takes a certain amount of time to ensure that the sheet is fully cured and has the required strength and stability.

Stripper and trim: Once the cast plate is fully cured, it can be removed from the mold. It is then trimmed and shaped to remove any excess edges or irregular parts and to smooth the surface of the sheet.

Quality inspection and packaging: Quality inspection is conducted to ensure that the dimensions, appearance and physical properties of the poured plates are in conformity with the requirements. The sheet is then packed to protect its surface from scratches or damage.

The casting process can achieve a variety of shapes, thicknesses and sizes of acrylic products. It has a high degree of freedom and creativity, can produce unique artworks, decorations, signs, display boxes and so on. Our company adopts advanced casting plate technology, committed to providing high quality, precise production of casting plate products, to meet customer needs and creativity.